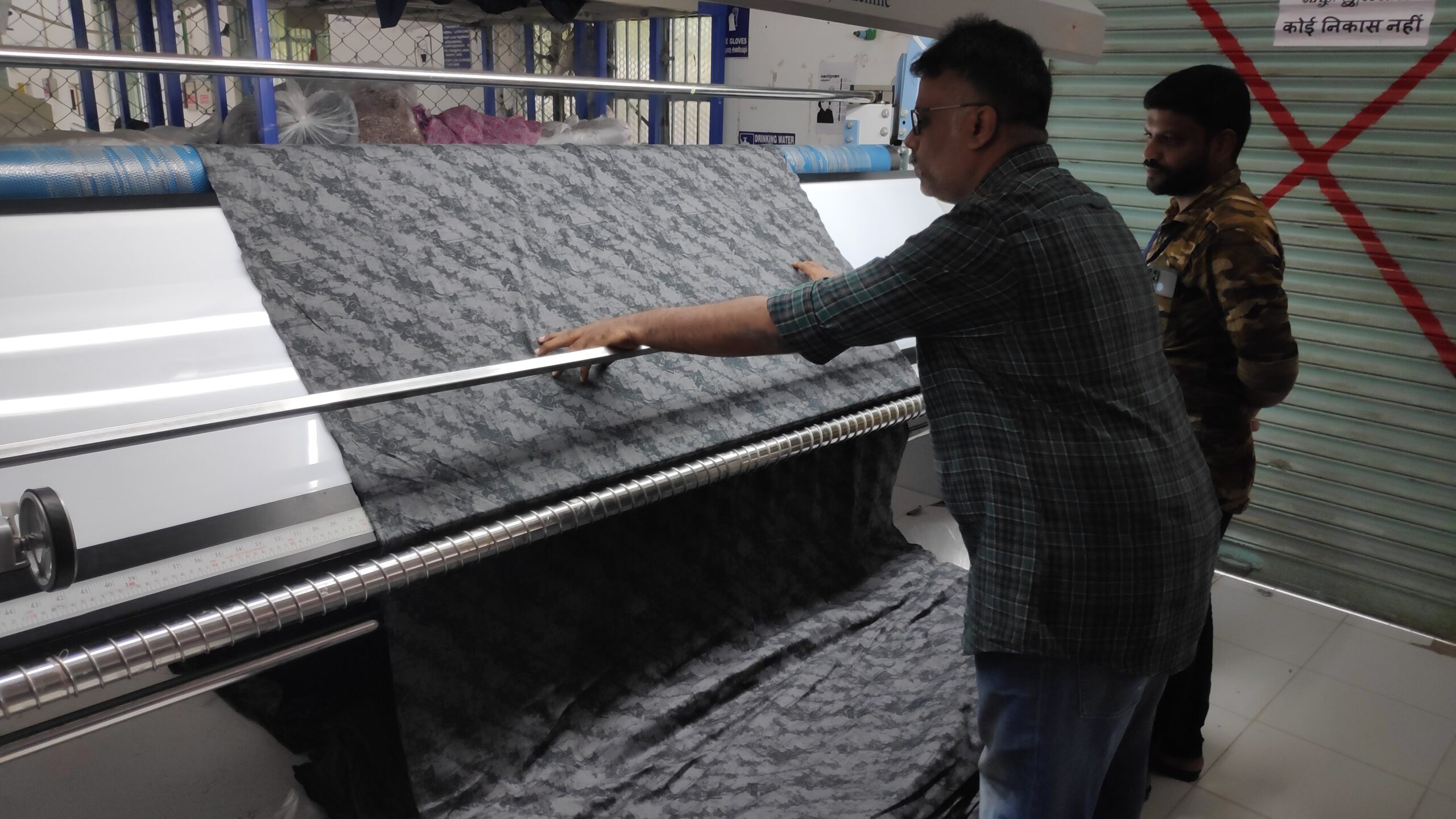

SDI – QA: Checking size spec during inline check @ factory.

Quality is one of those words everyone uses, but few stop to truly define. It’s often treated as a final hurdle, a last inspection before a product ships. Yet, in reality, quality doesn’t live at the end of the process. It lives in every decision that comes before it.

From the moment a product is conceived, quality is already taking shape. It’s influenced by how materials are selected, how specifications are interpreted, and how closely processes are followed once production begins. At Stars Design Group, quality is not reactive or accidental. It is intentional, structured, and built into the production lifecycle from day one.

This approach is made possible through the close partnership between Quality Assurance (QA) and Quality Control (QC). While the two functions are often spoken about together, their roles are distinct, and understanding how they work in tandem reveals why quality is not a single checkpoint, but a continuous system.

Quality Assurance: Designing Quality Before Production Begins

Factory Person monitoring all over print – bulk production @ printing unit

Quality Assurance sets the tone for everything that follows. Long before machines are running or materials are cut, QA is already at work defining what quality should look like and how it will be achieved.

Rather than focusing on catching mistakes, QA focuses on preventing them. This includes validating specifications, reviewing materials, assessing risk, and establishing pre-production controls that ensure expectations are clear, achievable, and aligned across teams. These early decisions shape how smoothly production runs and how consistently standards are met.

QA does not step away once production begins. Instead, it follows the product through its entire lifecycle, ensuring that processes remain aligned with the original intent. When quality is designed into the system this way, it becomes repeatable, scalable, and far less dependent on last-minute corrections.

SDI – QA: Performing fabric inspection – bulk lot @ factory premises.

Quality Control: Protecting Quality on the Production Floor

While QA is responsible for designing the roadmap, Quality Control ensures that the journey stays on course.

QC operates where production happens. As products move through manufacturing, QC teams provide real-time oversight monitoring workmanship, identifying defects as they emerge, and intervening before small issues become larger problems. This hands-on presence allows quality to be protected in the moment, not addressed after the fact.

By detecting issues early and applying corrective actions immediately, QC plays a critical role in maintaining efficiency while safeguarding consistency. It ensures that the standards defined through QA are not just theoretical, but actively upheld throughout production.

How Tolerance Is Defined Through the Consumer’s Eyes

Production floor making our styles

Not all defects are created equal, and quality decisions cannot be governed by rigid, one-size-fits-all rules. Acceptable tolerance levels vary depending on the product, its function, and how it will ultimately be experienced by the end consumer.

Rather than evaluating quality in isolation, tolerance is assessed through a consumer-centric lens. Any issue that impacts perception, functionality, or safety is considered a major defect, as it affects usability or market acceptance. Minor defects, by contrast, are those that are minimally noticeable and do not meaningfully affect performance, appearance, or salability.

This perspective ensures that quality standards are rooted in real-world expectations, prioritizing what matters most to the people who use the product.

SDI – Technician: Conducting style review meeting with factory team

Quality Across the Full Production Lifecycle

Quality Assurance and Quality Control are present at every stage of production, though their focus shifts as the process evolves. During active manufacturing, QC takes the lead, concentrating on monitoring, detection, and corrective control in real time. As production concludes, QA assumes primary responsibility for post-production validation, confirming that finished goods meet all defined specifications and compliance requirements before shipment.

Rather than operating in silos, QA and QC work in parallel. This continuity creates accountability, clarity, and consistency — ensuring quality is upheld not just at isolated moments, but throughout the entire lifecycle.

Building Quality Through Every Checkpoint

SDI – QA: Checking quantity check during SDI’s prefinal inspection

Quality should be woven into every stage of the supply chain, remaining present through to the final approval of finished goods. Fabrics and components are verified against specifications and supporting test reports before they are approved for use. Size sets are carefully reviewed to confirm measurements, fit, and construction prior to bulk production. As manufacturing progresses, ongoing evaluations allow teams to identify potential issues early and make adjustments before defects scale.

Before products leave the floor, a final assessment confirms that all requirements have been met. Each of these moments reinforces the same principle: quality is strengthened through consistency, attention, and follow-through at every stage.

SDI – QA: Checking carton markings during SDI’s prefinal inspection

Quality as a Commitment, Not a Final Check

The strongest quality programs are proactive by design. When Quality Assurance’s preventive framework is aligned with Quality Control’s real-time execution, risk is reduced, efficiency improves, and consistency becomes achievable at scale.

At Stars Design Group, quality is treated as a long-term commitment rather than a final inspection. It is built thoughtfully, reinforced continuously, and upheld by the teams who bring it to life every day. When quality is embedded into the process from the beginning, trust is earned and sustained at every stage.

About Stars Design Group: Founded by industry experts, Stars Design Group global fashion design and production house that helps clients bring their apparel to market. We consult, design, and facilitate production and delivery.

About Stars Design Group: Founded by industry experts, Stars Design Group global fashion design and production house that helps clients bring their apparel to market. We consult, design, and facilitate production and delivery.

Understanding that the apparel industry is about evolution and not revolution, we continue to refine the way the industry does business. Embracing the latest 3D design and development software, we help to refine the design and approval process in a digital landscape, paving the way for rapid decisions and execution of programs while reducing mistakes, improving fit, minimizing returns, and increasing profit margins.

With a network of 67 factories in 14 countries worldwide, our relationships are generations deep. Being diverse in our manufacturing locations, we are nimble in an ever-evolving landscape and provide ethically manufactured apparel and accessories.