Textile research is changing the future, and you didn’t even know it

Self-driving cars, artificial intelligence, civilian trips to Mars…the current technological landscape is exciting, and the future is full of potential. Amid all these high-profile technologies however, there have been massive advancements and research in areas that sometimes fly under the radar; areas that have enormous implications for the future of our daily lives. One of the most exciting and impactful of these is the area of textile materials and fibers research.

How will textile materials research change the way we live?

Humans have utilized textiles since the first Neanderthal placed the skin of an animal on his back for warmth. They play a large role in our lives whether we think about it or not. From creating sails large and strong enough to take humanity around the globe, to providing the necessary materials to float in outer-space, textiles have helped shape our history and our individuality. Textiles in fashion help to define one’s character and broadcast a personality. They keep us warm or cool, protect us from disease, allow us to interact with our world in ways we would otherwise be unable to. Naturally, as technological advancements allow for the creation of a more diverse set of textiles and fibrous materials, humanity’s capacity for growth and exploration increase as well.

Over the next few weeks I would like to share some of these advancements. The topic for this week:

Spider Silk – The web of the future.

Paired with the advances in mechanical and computational technology there have been significant technological leaps in our understanding of DNA and biological engineering. In an effort to produce stronger, more durable materials there has been an expansive amount of research placed into the production of spider silk over the past two decades.

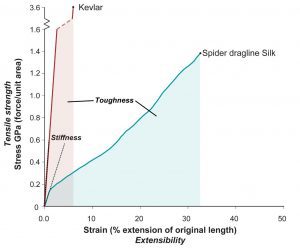

Spider silk has several properties that make it particularly attractive for mass production. It is a common mistake to confuse the properties of spider silk, so I will walk through it. Spider silk has both excellent tensile strength and extensibility, characteristics that, when combined, can be measured in toughness. Spider silk tensile strength is in the same ballpark as high-grade alloy steel (450−2000 MPa), and is about half as strong as materials such as Kevlar or Twaron(3000 MPa). However, due to its high degree of extensibility, basically its “stretchiness” under increased strain, spider silk is significantly tougher than either. It can stretch to greater than 20 times its original length without breaking, and maintains its materialistic properties under extreme temperatures (-4 to 626 degrees Fahrenheit!!!).

By The original uploader was Vincentsarego at English Wikipedia. – Transferred from en.wikipedia to Commons., CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=40001987

You can see that if we were able to produce spider silk in any quantity it would mean stronger and lighter cables for engineering, more durable clothing that could withstand the harshest of conditions, and many applications in medicine as well. The problem is the quantity. Spiders do not produce enough silk on there own to support “spider farms” and we have been unable to synthetically generate a compound similar to spider silk. So, what is the solution?

Spider Goats – The Cutting Edge of Textiles Research

This is the part where you stop and think to yourself “this is a satirical article, right?”….Nope. Spider Goats. I am not kidding.

Researchers at Nexia Biotechnologies, and later Utah State University and the University of Wyoming were able to create transgenic goats that, when milked, produce a spider silk-like protein in the milk. These proteins can be wet-spun to produce fibers or electro-spun to produce nanofibers and nanomeshes that equal or exceed the material properties of natural spider silk. This technology has actually been around for quite some time now, and Nexia Biotechnologies has begun expanding upon their original “Biosteel”, as they have marketed it, with a wide range of additional high-strength/toughness fibers.

So why haven’t these materials taken over the market?

While the ability to genetically modify goats to produce silk represents an enormous step towards our ability to mass-produce this material, it is unfortunately not enough to do so quite yet. The procedures involved in extracting and spinning the proteins into a usable fiber are still cumbersome and highly expensive. Continuing research looks promising however, and I believe that we can expect to see these materials become a staple in textiles and apparel manufacturing in the next decade.

But…..will they remain competitive in the market with rise of space-age graphene materials?……Find out by reading our blog next week!

About Stars Design Group: Founded by industry experts, Stars Design Group global fashion design and production house that helps clients bring their apparel to market. We consult, design, and facilitate production and delivery.

About Stars Design Group: Founded by industry experts, Stars Design Group global fashion design and production house that helps clients bring their apparel to market. We consult, design, and facilitate production and delivery.

Understanding that the apparel industry is about evolution and not revolution, we continue to refine the way the industry does business. Embracing the latest 3D design and development software, we help to refine the design and approval process in a digital landscape, paving the way for rapid decisions and execution of programs while reducing mistakes, improving fit, minimizing returns, and increasing profit margins.

With a network of 67 factories in 14 countries worldwide, our relationships are generations deep. Being diverse in our manufacturing locations, we are nimble in an ever-evolving landscape and provide ethically manufactured apparel and accessories.