Creating high-performance clothing is a challenging task that requires a deep understanding of fabric selection, functionality, design, fit, and garment construction. If one element is wrong, the garment may no longer function in the rigorous conditions of the activity. Adding to the complexity, some details may counteract each other, rendering one, or both ineffective. Every decision in the process is crucial to the effectiveness and performance of the garment.

“It’s not enough that a garment looks good or feels good anymore, everyone wants it to do something. Even if they don’t know what that something is!” ~ CEO, Bret Schnitker

Ergonomics and Design for the Target Consumer

Designing for performance requires an intimate understanding of the target consumer, their needs and their environment. Prioritizing functionality, fit, and comfort will result in high-quality garments that enhance the wearer’s performance and provide protection. Paying careful consideration to climate, movement and protective treatments can take the garment to the next level.

When designing for performance it is essential to start with a discussion about the movement, tasks performed and the needs of the target consumer. Stars Design Group CEO, Bret Schnitker says, “You’re going to be looking at ergonomics, you’re going to be looking at movement in particular ways. You’re going to be looking at venting, resistance to elements, different ways to construct a garment in terms of …. the ability to layer and un-layer”, among many other considerations.

When designing for performance it is essential to start with a discussion about the movement, tasks performed and the needs of the target consumer. Stars Design Group CEO, Bret Schnitker says, “You’re going to be looking at ergonomics, you’re going to be looking at movement in particular ways. You’re going to be looking at venting, resistance to elements, different ways to construct a garment in terms of …. the ability to layer and un-layer”, among many other considerations.

It’s not enough to just talk about the movement, in many cases performing the activity can provide additional context. Team members at Stars Design Group have been known to engage in performance activities with clients, immersing themselves in the experience to gain a deeper understanding of the requirements needed to be fully functional for optimum performance.

Schnitker says small performance details can sneak up on even the most experienced garment industry professionals, “different activities can have little twists and turns where the process of experimentation, the process of application is super important.” He suggests focusing on executing the activities and obsessing about the details, doing this over time will identify important functional details.

Schnitker says small performance details can sneak up on even the most experienced garment industry professionals, “different activities can have little twists and turns where the process of experimentation, the process of application is super important.” He suggests focusing on executing the activities and obsessing about the details, doing this over time will identify important functional details.

Another component to consider when designing performance garments is the customer’s body type. “Sometimes in a particular performance situation, the body types will be more linear because by nature, they burn fat at a very, very steady rate. They’re very much in shape, so they’re going to have a different body type in general. So understanding that customer and building garments to your demographic is super important.” Schnitker says.

Once a clear understanding of the needs are determined, it’s time to work through the details of construction.

Fabric and Stitch Selection for High-Performance Clothing

Fabric is the foundation of any garment, making it crucial to select the right materials to withstand the demands of the intended activity. When choosing fabric for performance wear, designers should consider the fabric’s content, structure, breathability, and technical finishes such as wicking, ultraviolet protection, and warmth retention.

Since performance wear prioritizes functionality over aesthetics, fabric decisions should be made in tandem with functional design, with a priority on performance.

Since performance wear prioritizes functionality over aesthetics, fabric decisions should be made in tandem with functional design, with a priority on performance.

Fabrics, and the fibers that make them, have different qualities. A hydrophobic fabric like polyester and nylon is not absorbent making it problematic for some activities. “If someone’s running and perspiring, the fabric alone is going to get pretty uncomfortable because you’re going to have these droplets of perspiration running down your body,” Schnitker says. Cotton is hydrophilic and will absorb perspiration, making it a worse choice for sweat inducing activities.

The quality of sewing thread and stitch selection also play vital roles in ensuring high performance. Selecting a thread with weaker qualities or a stitch type that can’t withstand the pressure on the seams during the activity can be detrimental to the performance of a garment.

Poly core threads can provide more stability if stitched in a proper way. Schnitker says “We’ve got all different types of stitches from basic safety stitches that go very, very fast, that may not provide the durability you want to more complicated things like marrow stitches or six over four flat locks, and those seam the garment together in a way that provides more durability under demanding conditions.”

Poly core threads can provide more stability if stitched in a proper way. Schnitker says “We’ve got all different types of stitches from basic safety stitches that go very, very fast, that may not provide the durability you want to more complicated things like marrow stitches or six over four flat locks, and those seam the garment together in a way that provides more durability under demanding conditions.”

Technical Finishes for Optimal Functionality

Technical finishes can make up for some of the fabric’s missing functionality. One of the most common finishes is wicking, which Schnitker says “takes hydrophobic fabrics like polyester, that don’t absorb water, and creates an action where that water moves across the surface much more quickly and allows for evaporation, which creates a cooling effect.”

There are a number of finish options, each offering a different feature which can provide the needed level of performance in the garment. Nano ceramic coatings are invisible water-based, breathable coatings that refract the suns energy to keep garments cooler and can also repel dirt and water. Ultraviolet protection, warmth retention, and far infrared, are also popular options when designing high-performance garments.

Finish technology is constantly evolving and Schnitker says Stars Design Group is keeping up “We’ve been involved in basic wicking to advanced micro-encapsulation for years. There’s this ability to encapsulate health additives into the fiber itself or the fabric itself.” For example, adding antimicrobial elements can protect the wearer from certain microorganisms, and vitamins can be released into the skin after applying friction to the fabric.

Finish technology is constantly evolving and Schnitker says Stars Design Group is keeping up “We’ve been involved in basic wicking to advanced micro-encapsulation for years. There’s this ability to encapsulate health additives into the fiber itself or the fabric itself.” For example, adding antimicrobial elements can protect the wearer from certain microorganisms, and vitamins can be released into the skin after applying friction to the fabric.

When choosing finishes for your garment, it is important to work with a team that has a good understanding of the nuances and variabilities within them because, as Schnitker says, the process of identifying and combining finishes can be incredibly complex. “If you’re using different treatments to achieve a multitude of performance-enhancing effects to the garment. Sometimes a specific decision you make for wicking and then a decision that you make for, an anti-soil, will cancel each other out.

Trims

After determining functional design, fabric, and finishes it’s time to make decisions on trims. This is a very important step that goes beyond design details and branding. Performance trims offer yet another option to add even more features to the garment.

After determining functional design, fabric, and finishes it’s time to make decisions on trims. This is a very important step that goes beyond design details and branding. Performance trims offer yet another option to add even more features to the garment.

Examples of performance trims include items such as reflective detailing which provides visibility at night, as well as waterproof zippers and seam taping which offer more protection to water-resistant pieces. “After the garment is all sewn, they actually apply this taping onto the garment, because every time you’re making a needle hole to sew something, little atoms of water can actually get through and the inside of your performance wear can get wet” Schnitker adds that there a number of trims available for performance wear, it is a matter of choosing the one that works best to meet the needs of the activity.

Performance trims are only effective if they are fixing an identified problem, so it is important to have a very good understanding of the person wearing the garment and the conditions they will be wearing it in.

Fit Testing

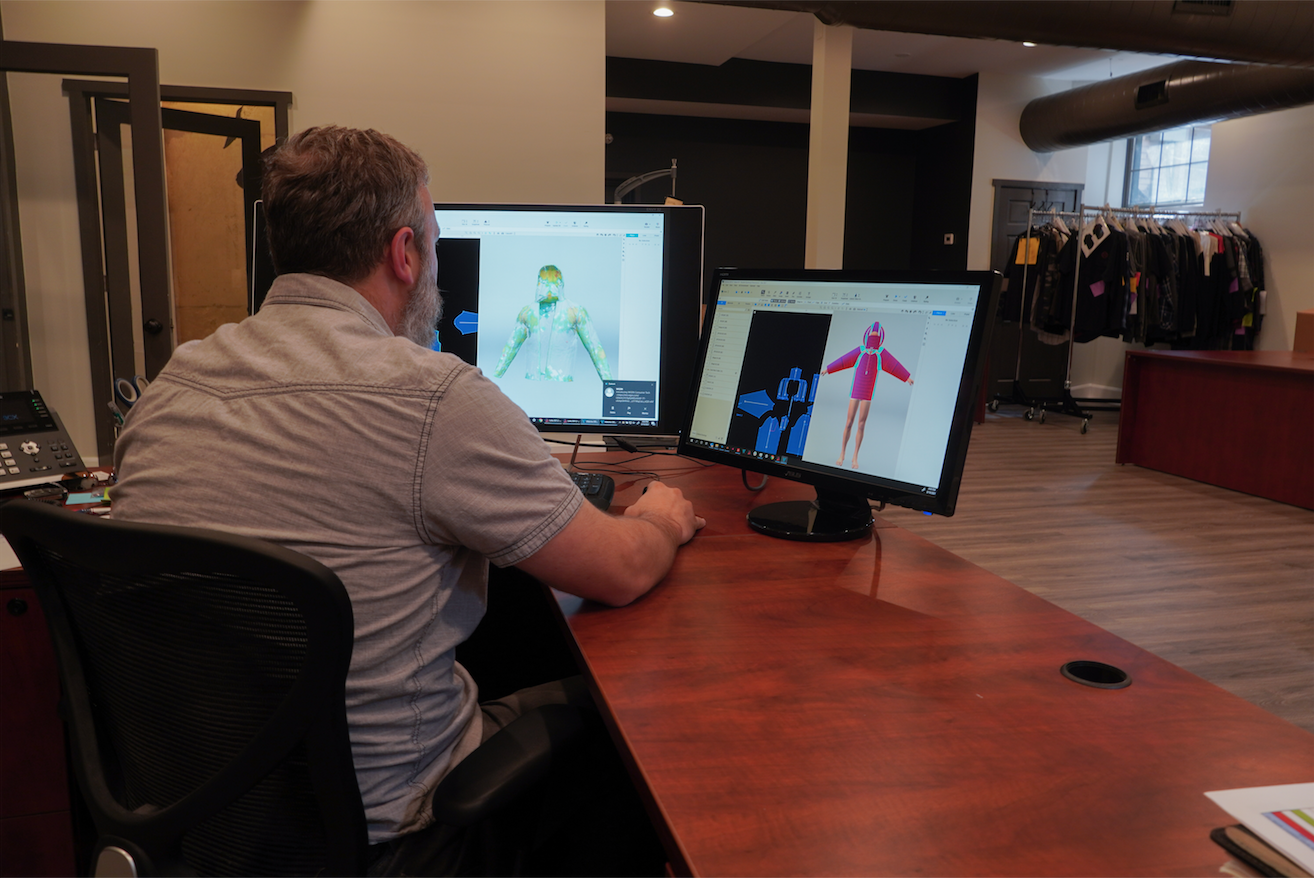

Once the ideal garment has been constructed, it needs to be tested for functionality. Stars Design Group utilizes 3D software to design the garments, this process allows us to conduct virtual fit tests to refine the garment in real time using 3D prototyping technology which you can see in the video below.

Once the ideal garment has been constructed, it needs to be tested for functionality. Stars Design Group utilizes 3D software to design the garments, this process allows us to conduct virtual fit tests to refine the garment in real time using 3D prototyping technology which you can see in the video below.

Schnitker says,“We can take an avatar in a virtual space that has these specific measurements for a key target demographic or a key target type of performance wearer, then take the pattern virtually, apply that to that particular avatar, apply grid mapping, put them in motion, and you can really see where fabric is tighter if you’re in a particular motion” This process allows SDG to make fit adjustments in real time, which can drastically reduce the number of adjustments on a physical garment.

Once the design has been refined in the virtual environment, physical samples will be made for a wear test. During this process, the garment is put through all the rigors of the activity to determine if there are any areas that need to be altered. If all of the steps outlined here are carefully considered, in many cases, the garment will only need minor adjustments, if any.

Conclusion

The key to creating optimal performance wear lies in a deep understanding of the target consumer’s needs and environment. This understanding guides the fabric selection, technical finishes, trims, and functional design required to create a garment that performs to the highest standards.

With the continued evolution of technology within the industry, the future of performance wear is very exciting, providing an opportunity to create even more innovative and high-tech solutions to improve garment functionality further.

Denise Naughton is an Emmy award-winning producer and journalist who has worked in all sides of media. At Stars Design Group, Denise uses her journalism and production expertise in support of all media and communication outreach.

is an Emmy award-winning producer and journalist who has worked in all sides of media. At Stars Design Group, Denise uses her journalism and production expertise in support of all media and communication outreach.