Last week I talked about the magical properties of spider silk and some surprising production techniques (Click here if you missed it!). Today I want to discuss a material I believe is truly representative of future textile technology. Graphene.

What is Graphene?

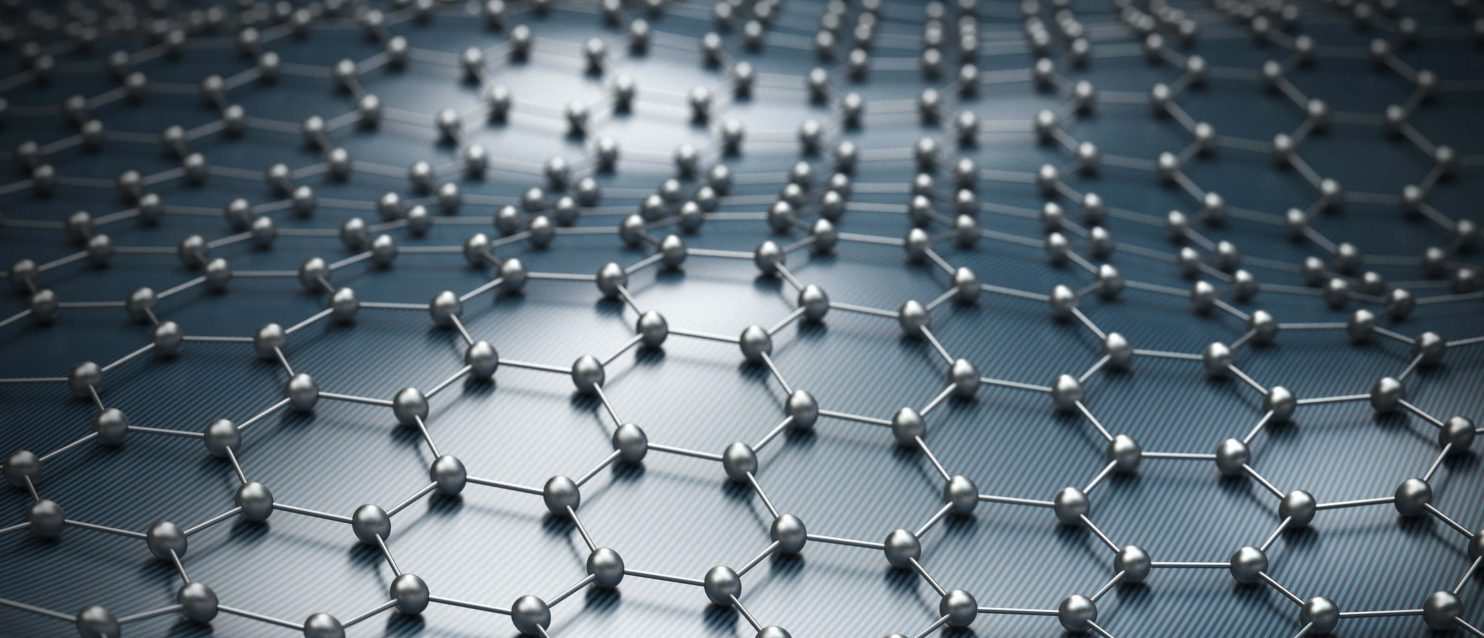

Graphene is, simply put, the thinnest form of graphite, the same kind you find in everyday pencils. Doesn’t sound too special, huh? I think I can convince you otherwise. Because of its unique structure and composition, graphene possesses an unbelievable set of materialistic properties.

Graphene sheets are practically two-dimensional, being only a SINGLE ATOM in thickness. For context, a single atom is approximately one-million times thinner than the width of a human hair…..try to wrap your head around that….

Graphene is extremely strong, light, flexible, naturally anti-bacterial, and conducts electricity and heat better than any other material we know of. Remember how strong spider silk is? If you coated a cluster of spider silk with graphene, you could create a cable strong enough to ostensibly catch a falling airplane.

Strength alone is not the reason I believe graphene will revolutionize apparel, however. Outside of its obvious durability, graphene’s ability to store and distribute heat could entirely recreate winter-wear. A company called Vollebak has just released one of the first Graphene jackets, made of a graphene-nylon blend. The jacket looks essentially like a high-quality rain-coat and retails at a whopping $695, but the performance claims are out of this world. The jackets are said to have incredible thermal conductivity and transfer heat equally around the body. Essentially, if your torso is warm, the jacket will send that heat to your arms as well, which are much harder to keep warm. These jackets can theoretically store an unlimited amount of heat and work like a radiator to keep the wearer warm. You don’t have to worry about getting too sweaty though since the graphene jacket also allows sweat to easily evaporate. The jackets are also anti-bacterial, and extremely durable. You can probably expect a graphene jacket to last you for your entire life.

Since graphene also possesses the ability to conduct electricity, it is reasonable to assume that apparel that can actually generate electricity is in the near future. Imagine being able to charge your phone by putting it in your pocket…I could definitely get behind that…Electrical conductivity also opens the door for a wide variety of material-integrated technology, which I may get into in another article (“E-parrel” and smart textiles are really interesting)

One more fun fact: researchers have successfully used graphene to build high-sensitivity textile gas sensors. By bonding graphene with molecular adhesives to common textile materials such as nylon, cotton, or polyester, the fabric can actually detect gas in the surrounding air. This has huge implications for emergency response, such as firefighters, who can be notified of air quality changes and the presence of hazardous gasses immediately, with no extra equipment.

Now, due to the cost and difficulty of production, it may be a while before products like this reach a reasonable price. However, the release of these early experimental textiles is extremely important for supporting ongoing research in the development of new products and graphene materials. It takes the tech out of the lab and into the hands of the users for real performance evaluation and feedback. I have only touched on the incredible properties of graphene material, but my aim is to get you excited and curious about the future of apparel. As always, I encourage you to continue the investigation on your own and be a part of emerging apparel technology!

About Stars Design Group: Founded by industry experts, Stars Design Group global fashion design and production house that helps clients bring their apparel to market. We consult, design, and facilitate production and delivery.

About Stars Design Group: Founded by industry experts, Stars Design Group global fashion design and production house that helps clients bring their apparel to market. We consult, design, and facilitate production and delivery.

Understanding that the apparel industry is about evolution and not revolution, we continue to refine the way the industry does business. Embracing the latest 3D design and development software, we help to refine the design and approval process in a digital landscape, paving the way for rapid decisions and execution of programs while reducing mistakes, improving fit, minimizing returns, and increasing profit margins.

With a network of 67 factories in 14 countries worldwide, our relationships are generations deep. Being diverse in our manufacturing locations, we are nimble in an ever-evolving landscape and provide ethically manufactured apparel and accessories.